CNC Turning

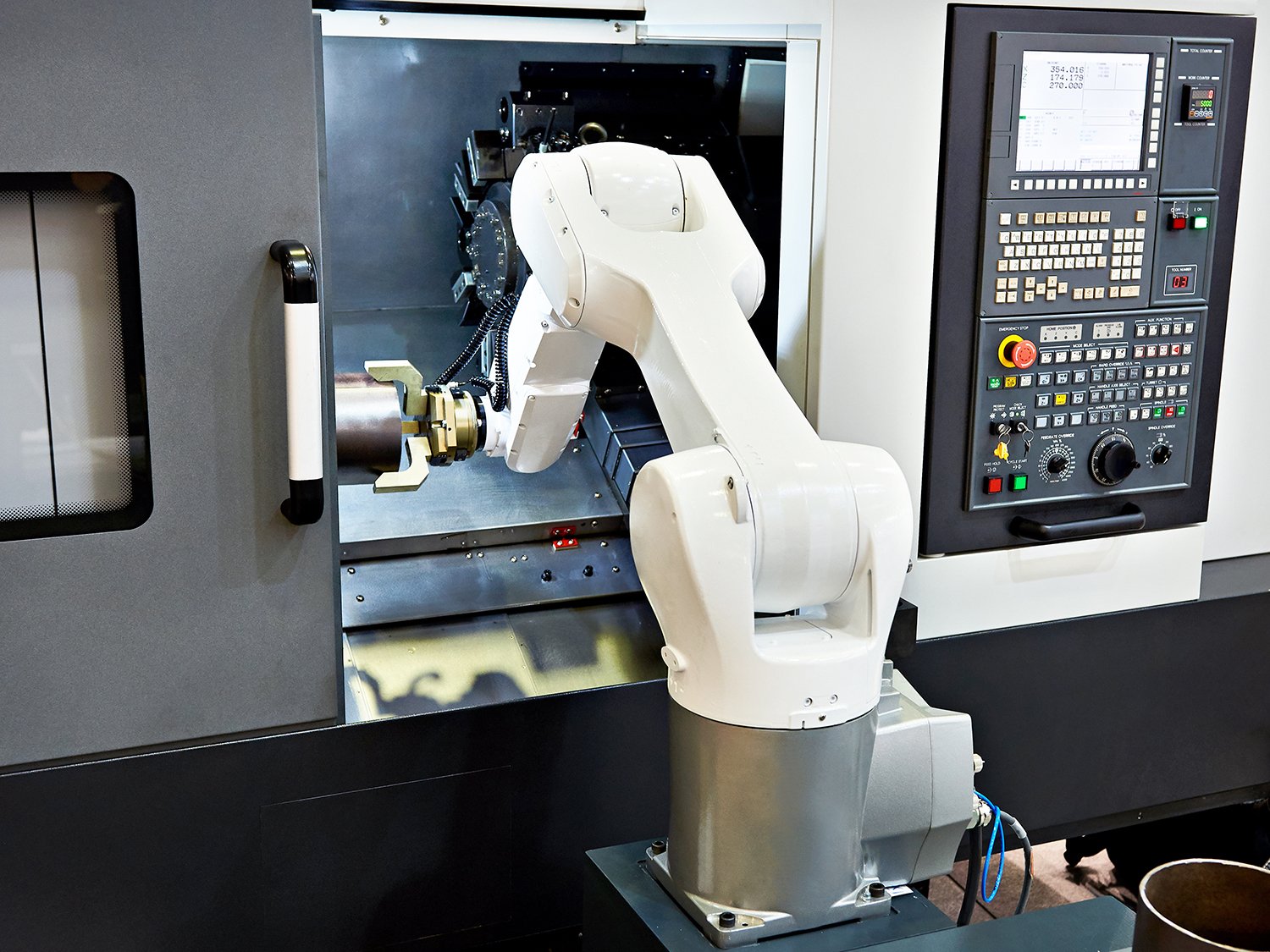

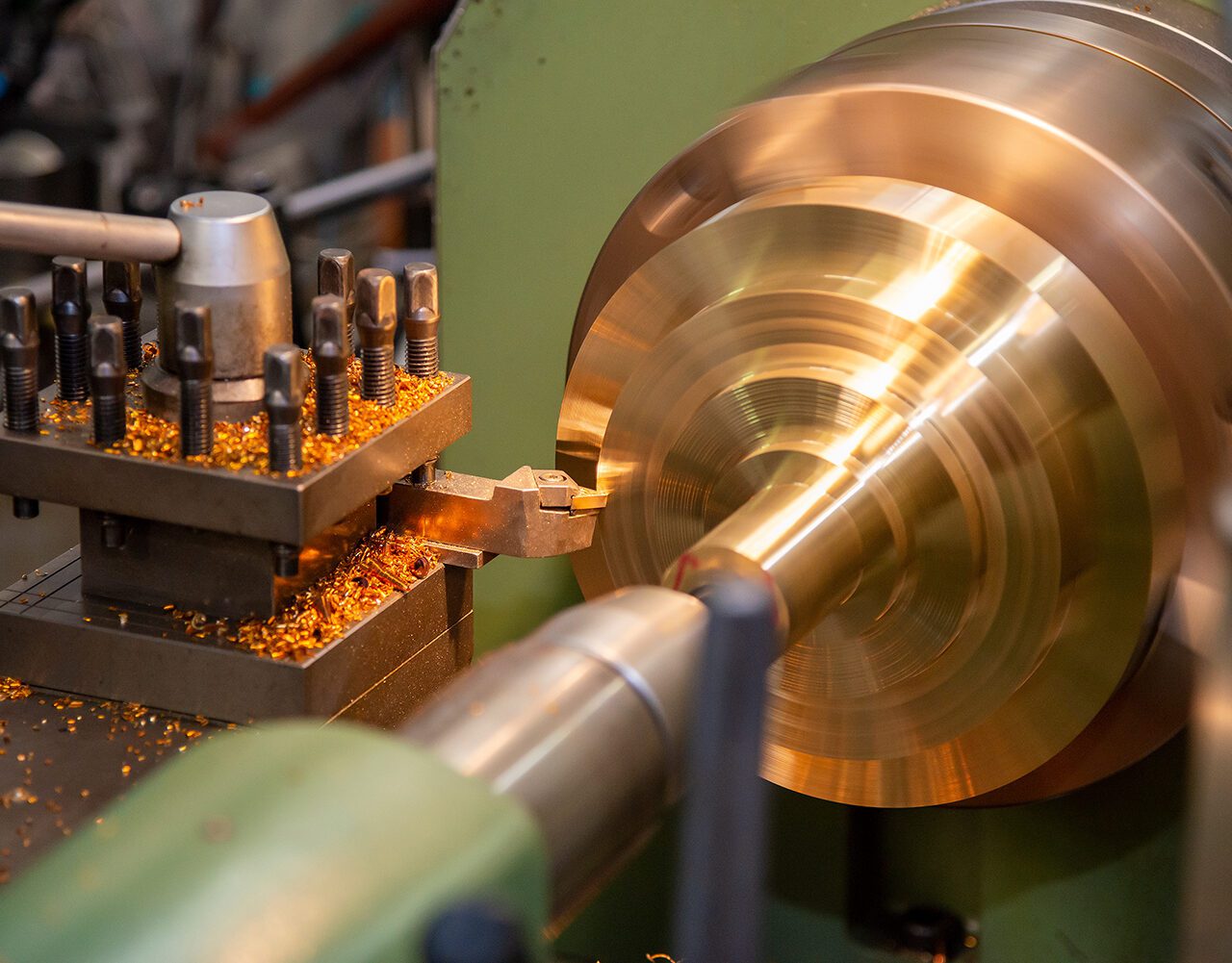

At Advanced Precision Machining (APM), we provide top-notch CNC turning services. An integral component of modern manufacturing, CNC turning is a highly precise machining process that plays a pivotal role in shaping a wide range of components. It involves the removal of material from a workpiece as it rotates on a lathe.

The process uses computer-controlled machines equipped with cutting tools that move along two axes of motion. As the workpiece rotates, the cutting tool expertly shapes the material, creating precise diameters, depths, and intricate geometries. CNC turning can be employed on the outer surface of cylindrical objects or internally, commonly known as boring, to craft tubular components.

CNC turning is critical in manufacturing due to its unrivaled precision and versatility. This process empowers us to transform raw materials into intricate components, meeting the most stringent quality standards and exact specifications.

CNC turning offers several advantages that revolutionize the manufacturing landscape. Its advanced capabilities enable us to achieve unmatched precision, consistent quality, and rapid turnaround times.

CNC Turning: An Overview

In the world of precision machining, CNC turning is arguably the cornerstone. The process melds technological prowess with exceptional craftsmanship and relies on a few vital components that work seamlessly to achieve remarkable results. Our state-of-the-art machine shop at APM boasts cutting-edge tools and technologies to ensure unparalleled precision.

The Key Components of CNC Turning

The CNC system serves as the brain of the operation, interpreting digital instructions and translating them into precise movements. It orchestrates the entire turning process, ensuring consistent results and eliminating human error.

The Advantages of CNC Turning

CNC turning accommodates a wide range of materials, including metals, plastics, and composites. Its versatility extends to complex geometries, enabling the production of diverse components for various industries.

The Applications of CNC Turning

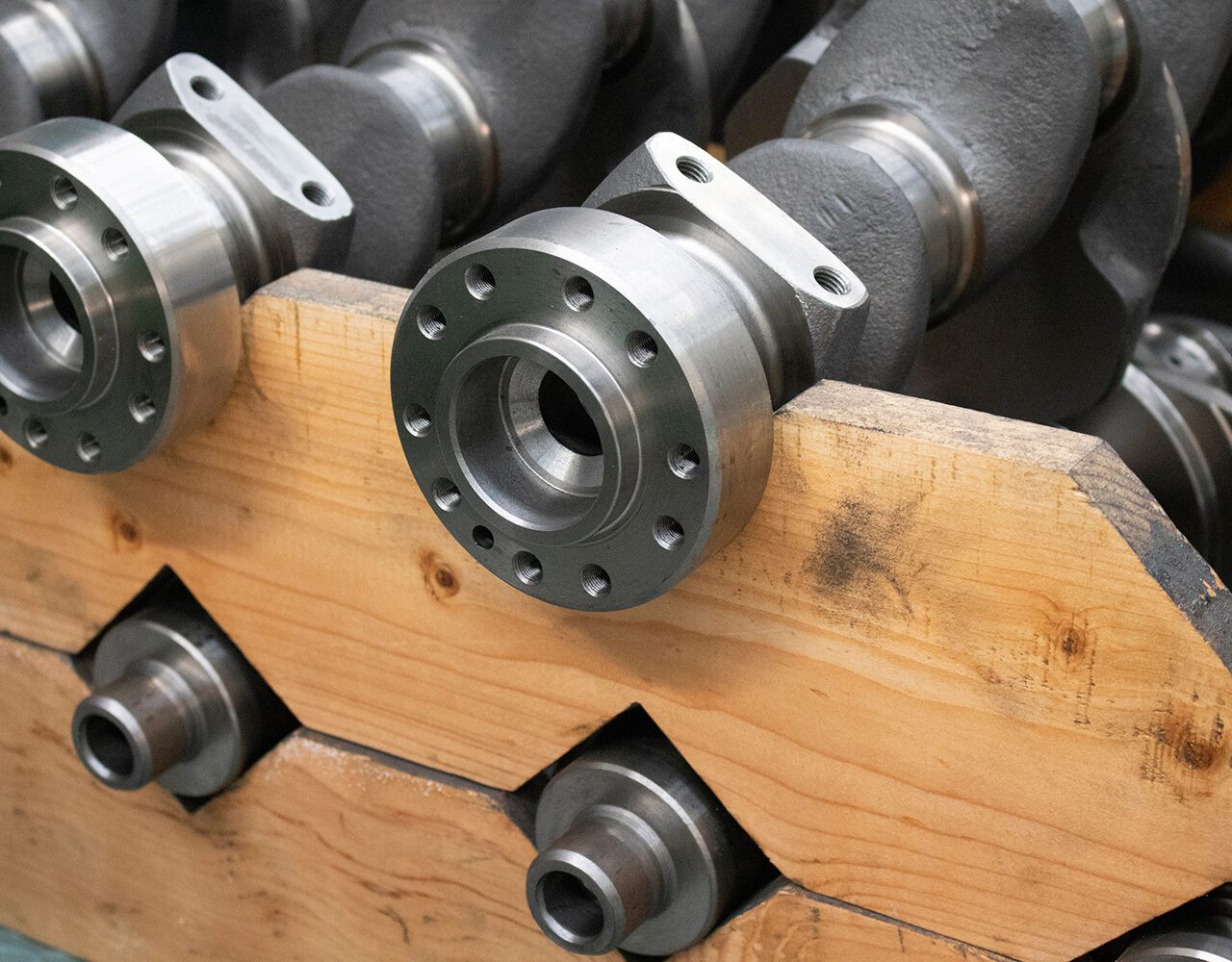

CNC turning finds extensive applications across automotive, aerospace, medical, electronics, and more industries. It is instrumental in manufacturing components such as shafts, bushings, flanges, pulleys, and custom parts with exceptional precision and reliability.

Types of CNC Turning Machines

CNC turning machines come in various configurations, each designed to cater to specific manufacturing requirements. Let’s take a look at the unique features of the three primary types:

Horizontal Machines

Horizontal CNC turning machines position the workpiece horizontally, allowing for efficient chip evacuation. This setup is ideal for large and heavy components that require sturdy support during the turning process. Horizontal machines excel in handling long workpieces and offer enhanced stability, making them suitable for applications where rigidity and precise cutting are crucial.

Vertical Machines

Vertical CNC turning machines position the workpiece vertically, enabling gravity to aid in chip removal. This configuration is advantageous for smaller components and intricate operations. Vertical machines offer easy access to the workpiece, simplifying tool changes and reducing setup times. They are known for their versatility, making them a popular choice for industries that require a high degree of flexibility and rapid production.

Swiss-Type Machines

Swiss-type CNC turning machines, also known as Swiss lathes or sliding headstock lathes, possess a unique design that sets them apart. These machines feature a guide bushing near the cutting area, allowing for excellent precision and control. Swiss-type machines excel in producing long, slender components with intricate details, making them highly suitable for industries such as medical and watchmaking. They offer exceptional accuracy and can handle complex geometries with ease.

While each machine brings its own set of advantages, there are key differences that set them apart. Horizontal machines excel in handling large, heavy components and offer stability during cutting, whereas vertical machines prioritize accessibility, quick tool changes, and versatility for smaller components. Swiss-type machines specialize in precise and intricate work, making them ideal for slender and complex parts.

Ultimately, the best machine for the job depends on factors such as the size and complexity of the components, production requirements, and industry-specific needs. Our team at APM is well-equipped with diverse CNC turning machines, ensuring that we can cater to a wide range of projects with utmost precision and efficiency.

The CNC Turning Process

The CNC turning process transforms raw materials into meticulously crafted components with exceptional precision. It includes the following steps:

Safety Precautions and Best Practices

Safety is paramount in CNC turning operations. Here are some essential precautions and best practices to follow:

Proper Training

Operators should receive comprehensive training on CNC turning machines, including safe operation, tool handling, and maintenance procedures.

Personal Protective Equipment (PPE)

Operators must wear appropriate PPE, such as safety glasses, gloves, and protective clothing, to safeguard against potential hazards.

Machine Maintenance

Regular maintenance and inspections ensure the CNC turning machine operates smoothly and minimizes the risk of malfunctions or accidents.

Tooling Safety

Inspect and maintain cutting tools regularly to ensure their sharpness, integrity, and proper installation. Follow safe tool change procedures to prevent injuries.

Chip Management

Proper chip management is crucial for a safe working environment. Clear chips regularly and use chip guards or chip conveyors to prevent chip accumulation and potential hazards.

Emergency Procedures

Familiarize operators with emergency shutdown procedures, fire prevention protocols, and the location of safety equipment like fire extinguishers and emergency stop buttons.

By adhering to these safety precautions and best practices, CNC turning operations can be carried out with the highest level of safety, efficiency, and quality.

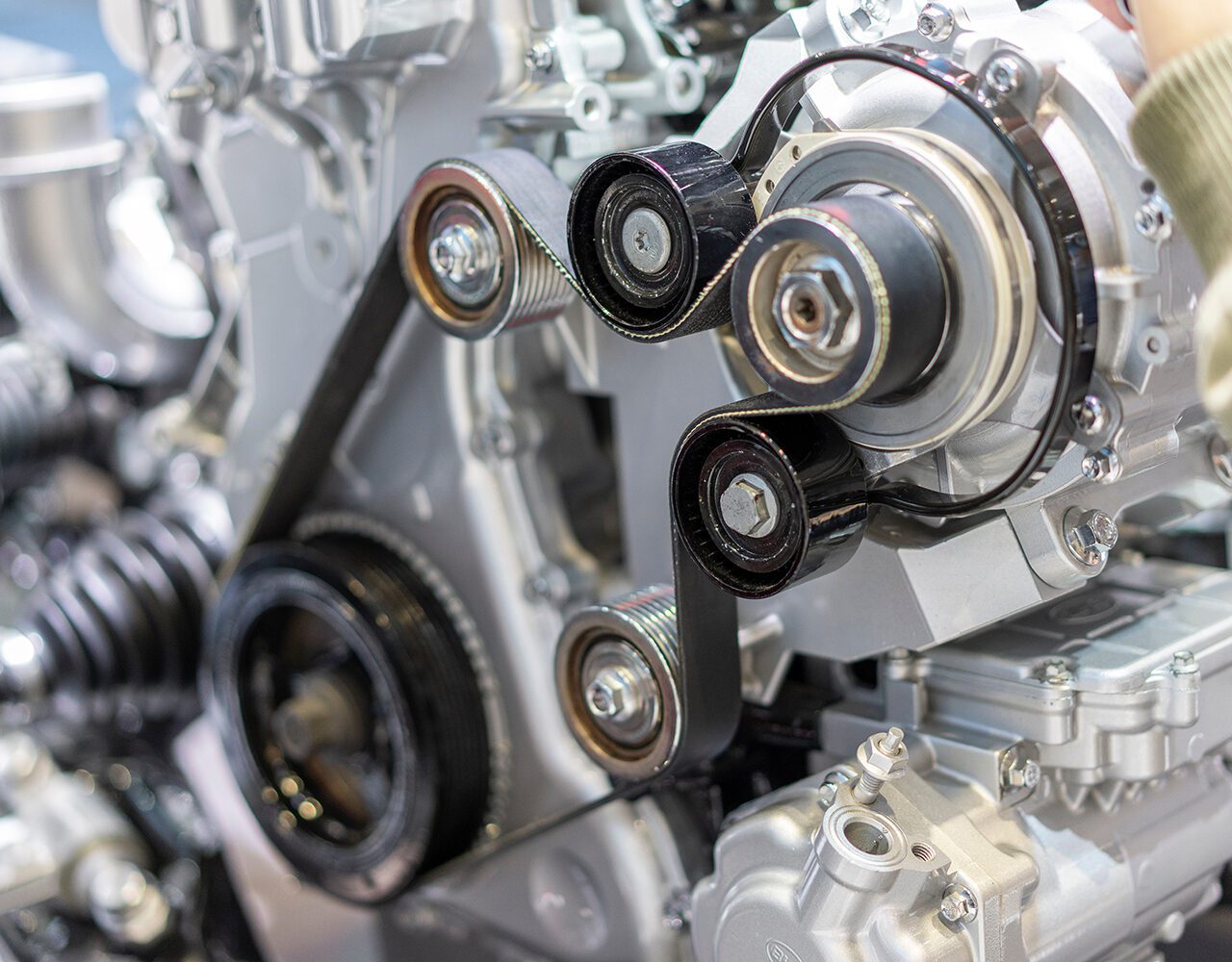

Automotive

CNC turning is widely employed in the automotive industry for manufacturing critical components such as shafts, flanges, pistons, and engine parts. It ensures precise machining and excellent dimensional accuracy, contributing to the overall performance and reliability of vehicles.

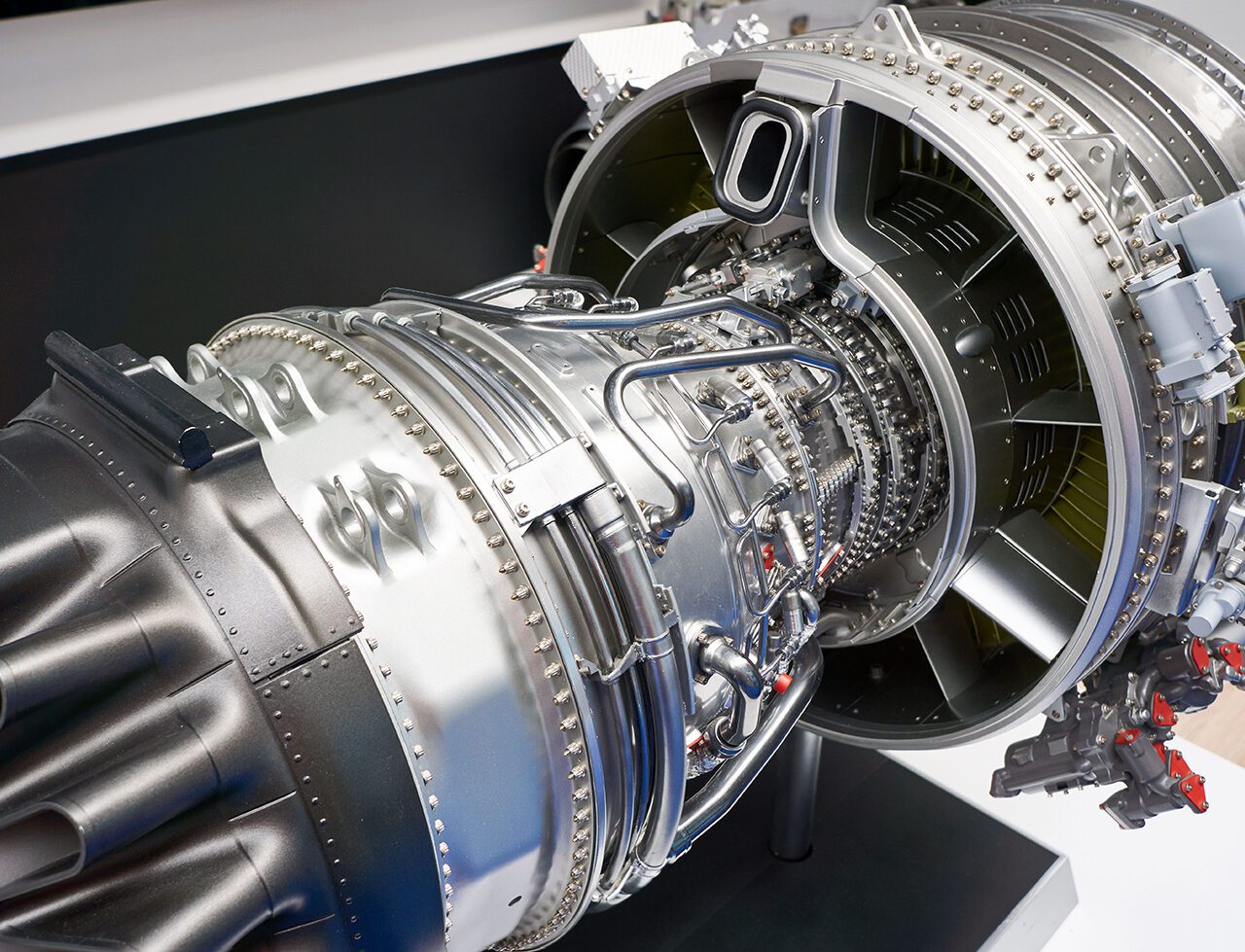

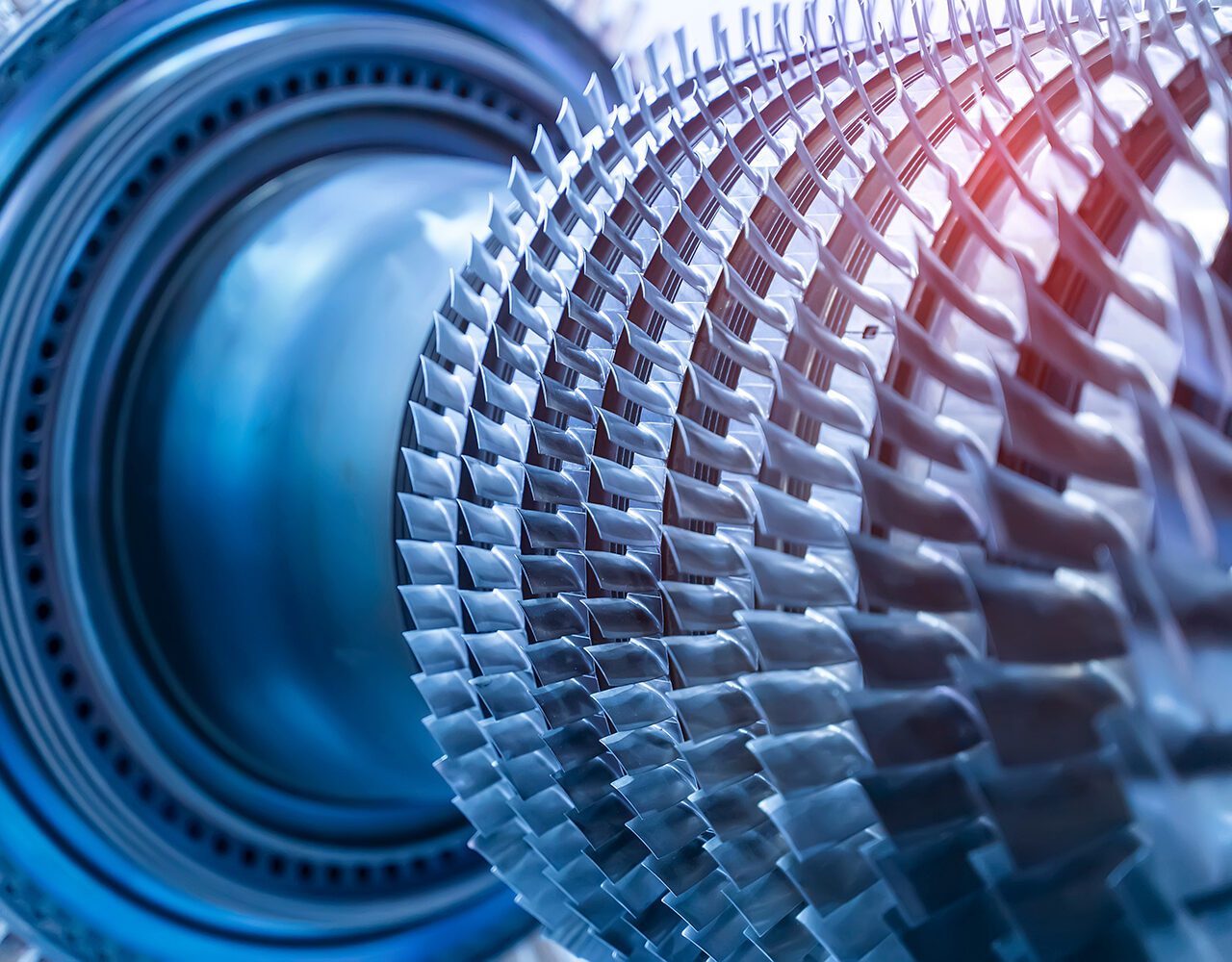

Aerospace

The aerospace industry relies heavily on CNC turning to produce intricate and high-precision components used in aircraft engines, landing gear, control systems, and structural parts. CNC turning enables the fabrication of lightweight yet robust components that meet stringent safety and performance requirements.

Medical

CNC turning plays a vital role in medical device manufacturing, producing components like surgical instruments, implants, prosthetics, and dental parts. The exceptional precision and customization capabilities of CNC turning ensure the production of intricate geometries and precise dimensions critical for medical applications.

Electronics

CNC turning is indispensable in the electronics industry for manufacturing components such as connectors, housings, terminals, and heat sinks. It enables precise machining of intricate designs and ensures proper fit, functionality, and reliability in electronic devices.

Custom Parts

CNC turning is ideal for producing custom parts tailored to specific requirements. Whether it’s for machinery, equipment, or specialized applications, CNC turning allows for the creation of unique components with precise dimensions and complex geometries.

Prototyping and Model-Making

CNC turning is extensively used in prototyping and model-making industries to transform design concepts into physical prototypes. It enables the production of accurate prototypes for product testing, evaluation, and refinement before full-scale manufacturing.

Artistic Projects

CNC turning has found its way into the realm of artistic projects, allowing artists and artisans to create intricate and sculptural pieces. From decorative elements to artistic sculptures, CNC turning offers precise control over material shaping, enabling the realization of intricate artistic visions.

CNC Turning Services

Custom CNC Turning Services

Our custom CNC turning services empower you to bring your unique designs and concepts to life. We understand that every project has distinct requirements, and our team of highly skilled machinists is equipped to handle the most complex and precise specifications. Whether it’s a one-off component or a large-scale production run, we work closely with you to ensure that your vision is realized with meticulous attention to detail.

Material Selection and Sourcing

With an extensive network of trusted suppliers, we offer a wide range of materials to choose from for your CNC turning projects. From common metals like aluminum and steel to exotic alloys, we help you select the most suitable material based on your specific requirements. Our commitment to quality extends to the sourcing of materials, ensuring that we use certified and traceable materials for your projects.

Quality Control and Inspection

Maintaining the highest standards of quality is at the core of our CNC turning services. We implement rigorous quality control measures throughout the entire manufacturing process, from initial material inspection to final component evaluation. Our skilled inspectors utilize advanced measurement techniques and equipment to verify dimensional accuracy and adherence to specifications, ensuring that each component meets or exceeds your expectations.

Pricing, Turnaround Times, and Order Requirements

Material Selection Guide

Aluminum

- Properties: Lightweight, excellent machinability, corrosion-resistant, good thermal and electrical conductivity.

- Advantages: High strength-to-weight ratio, versatility, cost-effective, suitable for intricate designs.

- Common Applications: Aerospace components, automotive parts, electronic enclosures, decorative elements.

Steel

- Properties: High strength, durability, excellent machinability, good thermal conductivity.

- Advantages: Wide range of alloys available, high load-bearing capacity, suitable for high-stress applications.

- Common Applications: Shafts, gears, fasteners, tooling components, automotive and industrial parts.

Stainless Steel

- Properties: Corrosion-resistant, high tensile strength, heat-resistant, excellent machinability (varies by grade).

- Advantages: Hygienic properties, suitable for harsh environments, aesthetically appealing, diverse range of grades available.

- Common Applications: Medical instruments, food processing equipment, automotive components, architectural elements.

Brass

- Properties: Good machinability, corrosion-resistant, excellent electrical conductivity.

- Advantages: Attractive appearance, anti-sparking properties, suitable for decorative applications, easy to solder and join.

- Common Applications: Fittings, connectors, electrical components, musical instruments, plumbing fixtures.

Plastics (e.g., Nylon, Delrin, PEEK)

- Properties: Lightweight, low friction, chemical resistance (varies by type), excellent dimensional stability.

- Advantages: Wide range of properties available, cost-effective, suitable for intricate designs and complex geometries.

- Common Applications: Bearings, bushings, gears, medical devices, electrical insulators, consumer products.

Titanium

- Properties: Lightweight, high strength, excellent corrosion resistance, low thermal conductivity.

- Advantages: High-performance material, biocompatible, suitable for aerospace and medical applications, exceptional strength-to-weight ratio.

- Common Applications: Aircraft components, medical implants, sporting goods, marine equipment.

When selecting a material, consider factors such as mechanical properties, environmental conditions, aesthetics, and regulatory requirements. Our team at APM is well-versed in material selection for CNC turning and can provide further guidance to ensure the optimal choice for your specific project.

Machining Capabilities

At APM, our CNC turning services offer a wide range of machining capabilities to meet your specific requirements. With state-of-the-art equipment and a team of skilled professionals, we deliver exceptional precision and quality.

Our CNC turning services encompass a variety of operations, including facing, external and internal turning, grooving, threading, and more. We can handle both small and large-scale projects with precision and efficiency.

Let’s delve into the specific machining capabilities and capacities of our CNC turning service while highlighting maximum part dimensions, weight limits, and other specifications you should be aware of.

Machine Specifications and Capacities

- Maximum Part Dimensions: Our CNC turning capabilities accommodate parts with maximum dimensions of:

- Weight Limits: Our machines can handle components weighing up to:

- Chuck Size: We offer a range of chuck sizes to accommodate various part diameters, ensuring secure and stable holding during the turning process.

- Spindle Speeds: Our CNC turning machines feature adjustable spindle speeds, allowing for optimal cutting performance based on the material and operation.

- Tooling: We utilize a wide range of cutting tools, inserts, drills, and boring bars to achieve precise and accurate results across different materials and geometries.

- Tolerances: Our CNC turning services adhere to tight tolerances, ensuring dimensional accuracy and consistency.

It’s important to note that the specific machining capabilities, part dimensions, weight limits, and other specifications may vary based on the complexity of your project. Our team at APM is dedicated to working closely with you to understand your unique requirements and provide tailored solutions to meet your need

Surface Finishing Options

At APM, we understand that the surface finish of CNC-turned parts is crucial for both aesthetic appeal and functional performance. To meet your specific requirements, we offer a range of surface finishing options that enhance the appearance, durability, and functionality of the components. Let’s explore the various techniques and processes available to achieve exceptional surface finishes on CNC-turned parts.

Polishing

Polishing is a process that involves smoothing the surface of the part using abrasives, resulting in a glossy and reflective finish. It enhances the visual appeal of the component, providing a clean and professional appearance. Polishing can be tailored to achieve different levels of surface smoothness, depending on your desired outcome.

Anodizing

Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum parts. This process not only enhances corrosion resistance but also offers opportunities for coloring the component. Anodized parts can be produced in a wide range of colors, providing both aesthetic appeal and increased durability.

Coating and Painting

Coating or painting the CNC-turned parts provides additional protection, improves wear resistance, and adds an appealing finish. Various coating options, such as powder coating or liquid painting, can be applied to achieve the desired appearance, texture, and level of protection. Coatings can range from decorative finishes to functional coatings like corrosion-resistant or non-stick coatings.

Plating

Plating is a process where a thin layer of metal, such as chrome, nickel, or gold, is applied to the surface of the part. Plating enhances the aesthetics, provides corrosion resistance, and improves wear characteristics of the component. It offers a wide range of options for achieving decorative, functional, or protective finishes.

Other Finishing Techniques

Additional surface finishing techniques, such as bead blasting, engraving, or laser etching, can be employed to achieve specific visual effects, texture, or functional requirements. These techniques offer opportunities for customization and branding, allowing you to create unique and personalized CNC turned parts.

At APM, we work closely with our clients to understand their specific surface finishing requirements and offer guidance in selecting the most suitable option for their CNC turned parts. Our commitment to quality ensures that each surface finishing process is executed with precision and attention to detail, resulting in outstanding results.

Unleashing the Precision Potential of Our CNC Turning Services

CNC turning is a vital manufacturing process that offers precision, efficiency, and versatility in the production of cylindrical components. APM takes pride in offering comprehensive CNC turning services, providing exceptional quality, customization, and efficiency from blueprint to completion. By harnessing the power of state-of-the-art equipment and skilled professionals, we deliver precise, tailored solutions that meet the diverse needs of various industries.

CNC turning plays a crucial role in the manufacturing landscape, providing a range of benefits. Its importance lies in its ability to produce precise diameters and depths, create various shapes and geometries, and handle a wide range of materials. The benefits of CNC turning include increased productivity, reduced lead times, enhanced accuracy, improved repeatability, and the ability to produce complex components with high efficiency.

We hope this webpage has provided valuable insights into the world of CNC turning, its capabilities, and the multitude of benefits it offers. To further expand your knowledge and understanding of CNC turning, we recommend exploring the following reputable resources:

- Modern Machine Shop – The online platform of Modern Machine Shop provides a wealth of information on CNC turning, industry trends, techniques, and case studies. Visit their website: https://www.mmsonline.com/

- Manufacturing Tomorrow – Manufacturing Tomorrow is an industry-focused platform that covers the latest news, technologies, and advancements in manufacturing. It offers insights into CNC turning and its applications. Visit their website: https://www.manufacturingtomorrow.com/

- Cutting Tool Engineering – Cutting Tool Engineering is a magazine dedicated to providing information on cutting tools, machining processes, and industry trends. It offers valuable articles and resources on CNC turning. Explore their website: https://www.ctemag.com/

By exploring these resources, you can deepen your understanding of CNC turning and stay informed about the latest developments in the field.

Have Questions?

Frequently Asked Questions

- What materials can be used in CNC turning?

- What industries benefit from CNC turning services?

- How precise is CNC turning?

- Can you handle custom projects and prototypes?

- How do you ensure quality in CNC turning?

- What is the typical turnaround time for CNC turning projects?

- Can you handle high-volume production runs?

- How can I request a quote for CNC turning services?

- What sets your CNC turning services apart from others?

CNC turning can work with a wide range of materials, including metals like aluminum, steel, stainless steel, brass, and titanium, as well as engineering plastics such as nylon, PEEK, and acrylic.

Various industries benefit from CNC turning services, including automotive, aerospace, medical, electronics, and many others that require precision components for their products or equipment.

CNC turning offers exceptional precision, typically achieving tolerances as tight as a few thousandths of an inch (or a few hundredths of a millimeter). The precise nature of CNC turning ensures accuracy and consistency in the production of complex components.

Yes, at APM, we specialize in handling custom projects and prototypes. Our CNC turning services are flexible and can accommodate the unique requirements and specifications of custom projects and prototype development.

We ensure quality in CNC turning through various measures, including rigorous inspection processes, adherence to industry standards, skilled machinists, utilization of advanced metrology equipment, and a comprehensive quality control system to ensure precise and accurate results.

The turnaround time for CNC turning projects can vary depending on the complexity, size, quantity, and specific requirements of the project. At APM, we strive to provide efficient and timely services, and we work closely with our clients to establish realistic timelines based on their project needs.

Yes, our CNC turning services are equipped to handle high-volume production runs. With our state-of-the-art machinery and skilled team, we can efficiently produce a large quantity of precision components while maintaining quality and meeting project deadlines.

At APM, our CNC turning services stand out due to our commitment to exceptional quality, personalized customer service, extensive machining capabilities, adherence to tight tolerances, fast turnaround times, and our ability to handle custom projects. Our experienced team and state-of-the-art equipment ensure the delivery of high-quality precision components that meet the unique needs of our clients.

To request a quote for CNC turning services, you can visit our website and fill out our contact form. Provide details about your project, such as part specifications, quantities, materials, and any other relevant information. Our team will review your request and provide you with a comprehensive quote.