CNC Grinding

The modern manufacturing world is evolving fast, and it’s accompanied by an ever-growing demand for precise machining. Computer numerical control (CNC) grinding is at the heart of these emerging technologies. This advanced technique is known for its immense accuracy, which is necessary for producing incredibly precise parts.

CNC grinding is taking manufacturing by storm as it wields remarkable adaptability compared to traditional machining methods. Furthermore, it’s faster, safer, and more meticulous, so every workpiece that’s produced meets the exact specifications required.

Types of Grinding Machines

There are several different types of CNC grinding machines. Each is ideally suited for specific applications. Here are some of the most common kinds of grinders and the ways in which a precision grinding machinist might use each one:

Belt Grinder

The belt grinder is coated with an abrasive material that runs over the surface to be processed. It’s commonly used to shape and grind metal parts and can perform a variety of applications, including stock removal, deburring, and finishing.

Bench Grinder

A bench grinder is a manually operated tool that’s largely used to shape tool bits. The equipment has wheels that can grind, sharpen, and hone. Its applications vary depending on the grade and bond of the grinding wheel.

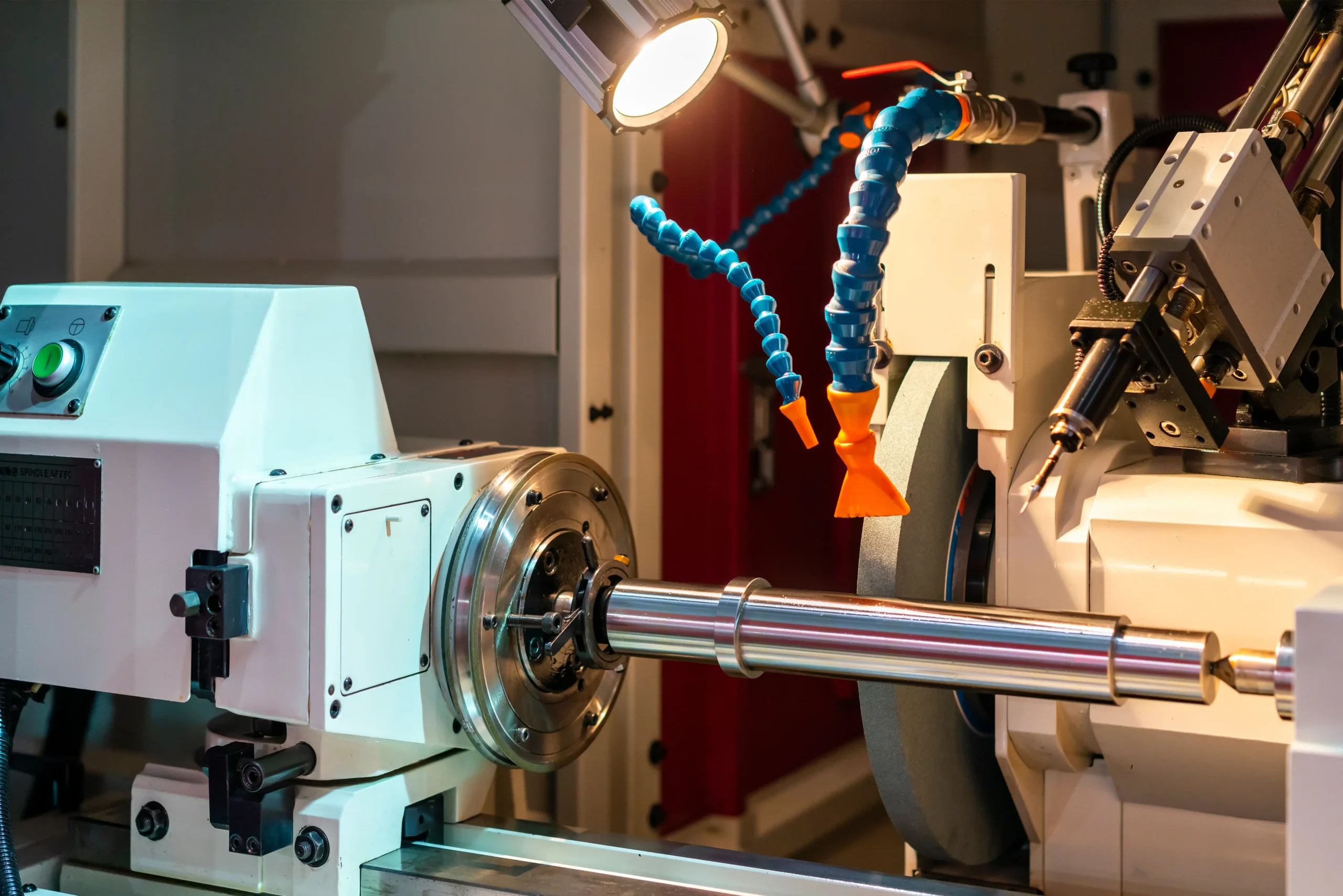

Cylindrical Grinder

The cylindrical grinder is used to make precision rods. This machine has multiple grinding wheels that form a cylinder to help shape the workpieces. CNC-operated cylindrical grinders are considered among the most reliable in the manufacturing industry and come in multiple types, including external, internal, universal, and centerless.

Surface Grinder

The surface grinder is equipped with a grinding wheel on which the workpiece is moved back and forth to produce a smooth finish. This grinder is widely used in abrasive machining processes.

Jig Grinder

The jig grinder is primarily used to grind holes, pins, and complex surface shapes. Every professional will tout this tool as a must in their grinding machine shop since it ensures a high degree of accuracy.

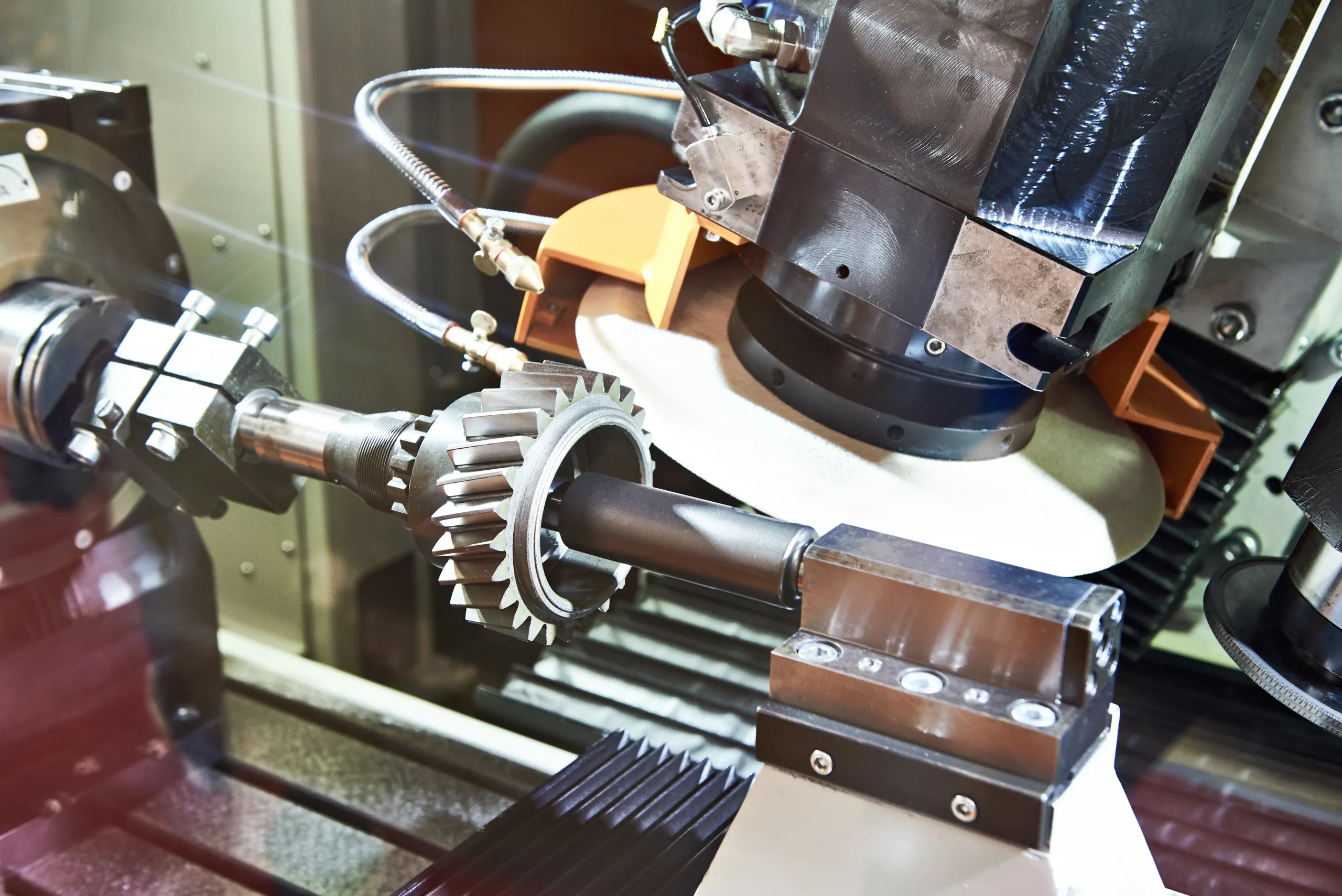

Gear Grinder

The gear grinder applies the final machining process when manufacturing high-precision gear. It does so by removing material from the gear’s tooth surfaces to achieve the desired shape, dimensions, and surface quality.

High-Precision Grinding and Machining Services

High-precision grinding and machining operations ensure a component’s dimensions conform to the tolerances set in place for its design. These services are especially crucial in grinding and machining, where a slight deviation from the desired specifications can lead to compromised functionality and increased wear over time.

Benefits of High-Precision Grinding and Machining

With high-precision processes, you can trust that every part meets the same exacting standards. Therefore, you can always count on your equipment to operate at maximum capacity when you need it most.

Why Choose APM

Advanced Precision Machining (APM) is your one-stop shop for high-precision grinding and machining. As trusted CNC precision grinding machinists, we’re dedicated to manufacturing parts that meet only the highest standards.

Our track record of delivering components that exceed expectations is a testament to our expertise and meticulous approach. If you decide to work with us, here’s what you can count on from our team:

- Exceptional Expertise: Backed by years of experience, our skilled machinists are equipped to produce complex parts with highly specific dimensions.

- Quality Assurance: Ensuring quality is ingrained in every step of our process. We deploy rigorous measures to guarantee every component leaves our shop flawless and ready to perform as intended.

- A Collaborative Partnership: If you turn to APM, you won’t be just another client; you’ll be a partner. We work closely with those we serve because we value cooperation and transparency, both of which are essential for making your vision a reality.

- Diverse Offerings: Our team produces components for a host of industries, including automotive, aerospace, and medical. That means we can meet virtually all your needs when it comes to precision parts.

What Is the Difference Between High-Precision Grinding and Machining and Regular Grinding and Machining?

1. Accuracy

Regular grinding and machining methods may provide acceptable results for components with looser tolerances; however, you need highly precise methods for parts requiring extremely tight tolerances or those that have incredibly intricate designs. Such methods guarantee accuracy down to micrometer levels, which is essential for industries in which even a slight deviation from the specifications can lead to performance issues or failures.

2. Surface Finish

While regular techniques can achieve acceptable finishes for many applications, some parts must meet stricter surface quality requirements. Examples include components that come into contact with delicate materials, require minimal friction, or demand optimal light transmission. This is where high-precision methods come in handy as they guarantee exceptionally smooth surface finishes.

3. Consistency

Regular grinding and machining will often achieve satisfactory consistency for standard applications. Only high-precision grinding and machining can duplicate thousands of parts to the same exacting standards, however, minimizing variability and enhancing reliability.

4. Longevity

Components produced using regular grinding and machining might develop premature wear and tear, particularly in demanding applications. On the other hand, high-precision techniques yield incredibly durable parts due to their optimized fits and superior surface finishes. The resulting longevity reduces maintenance costs in the long run and enhances overall system performance.

Understanding the Grinding Process

During the grinding process, the material is removed from the workpiece using an abrasive wheel, stone, or belt. The goal is to achieve tight tolerances and fine finishes. Considered a precise method of modification, grinding can be used on both metal and non-metal materials.

To achieve the desired results, the process begins with selecting the appropriate machine and an adequate wheel and then fine-tuning the grinding parameters. Let’s take a closer look at each step:

Understanding the Grinding Process

During the grinding process, the material is removed from the workpiece using an abrasive wheel, stone, or belt. The goal is to achieve tight tolerances and fine finishes. Considered a precise method of modification, grinding can be used on both metal and non-metal materials.

To achieve the desired results, the process begins with selecting the appropriate machine and an adequate wheel and then fine-tuning the grinding parameters. Let’s take a closer look at each step:

Precision Grinding Techniques

There are various precision grinding techniques that can help you achieve the desired results for your project. They include:

1. Centerless Grinding

The centerless grinding technique is used when working on long, thin workpieces. Two wheels are typically used: the abrasive grinding wheel and the regulating wheel. They move at different speeds, with the former moving faster than the latter.

2. Double-Disc Grinding

This precision technique relies on a pair of discs, which remove material from both sides of the piece simultaneously. As such, it can yield surfaces that are both flat and parallel during a single operation.

3. Cylindrical Grinding

The cylindrical grinding technique is one of the most common methods and uses a precision grinding wheel with a chuck that drives the workpiece. During cylindrical grinding, the disc and the workpiece rotate in different directions to ensure easy chip removal.

4. Surface Grinding

This is a precision grinding technique used to produce a smooth finish on flat surfaces. Whereas the cut of a cylindrical grinding machine is round, the surface grinding machine cuts in a flat shape.

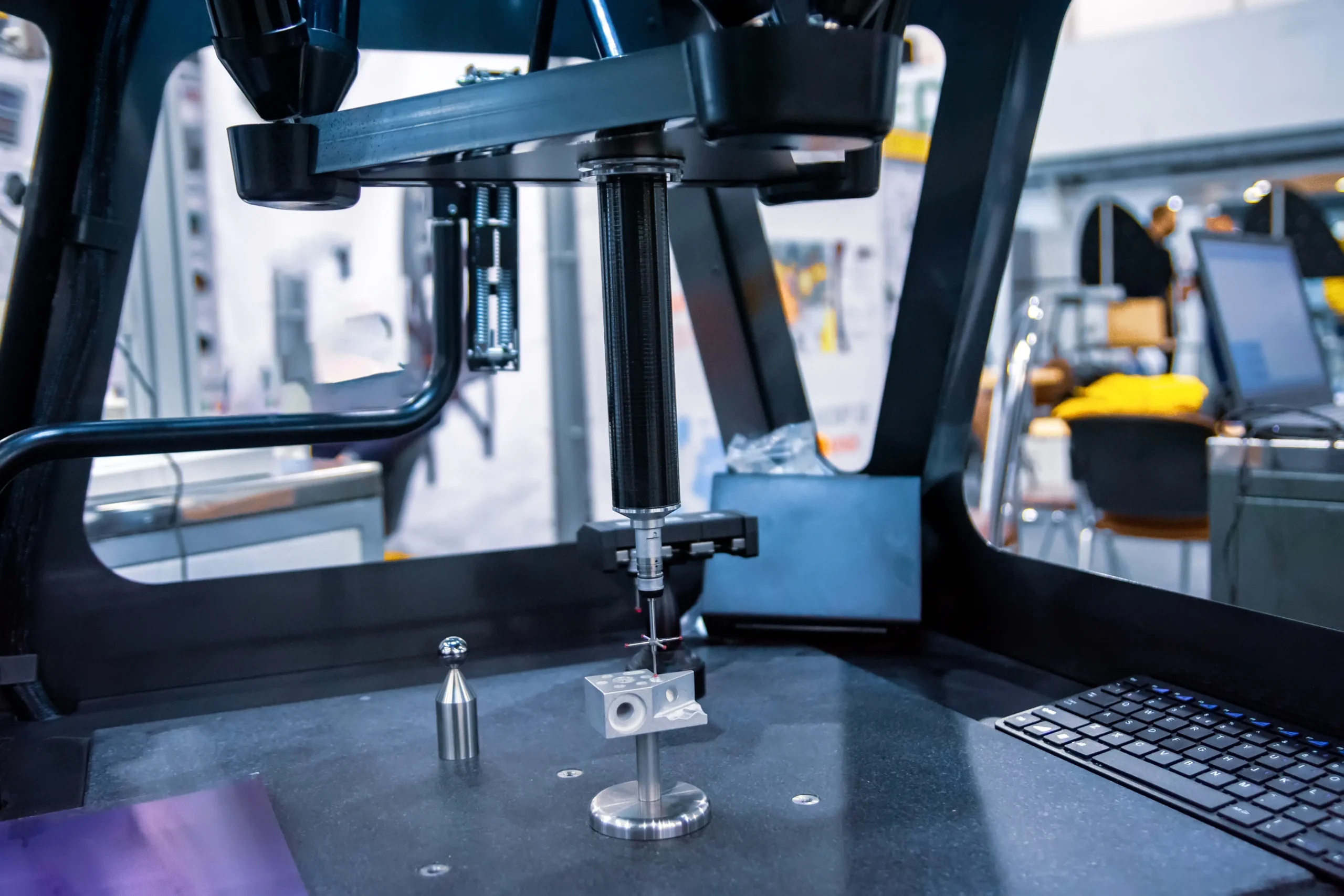

Ensuring Accuracy in Grinding and Machining

The level of accuracy in high-precision grinding and machining is primarily controlled by the computer’s settings, which are responsible for directing the tool’s movements. However, there are a few additional factors that can enhance accuracy. These include:

- The Quality of the Tools: While the movements in CNC grinding are controlled by a computer, you must use the right tools for the job—and calibrate them properly—to ensure optimal results.

- The Material’s Properties: It’s important to consider things like yield strength and thermal expansion before grinding begins. When subjected to the same cutting force, materials with a low yield strength are more prone to being deformed than those with a high yield strength.

- The Equipment’s Grade: The most accurate parts come from grinding machine shops that use advanced machinery with superior quality. This equipment is designed to minimize vibrations and maintain stable conditions for accurate operations.

- Proper Alignment: Proper alignment of components, such as grinding wheels and workpieces, prevents deviations that could compromise precision.

Ongoing Feedback: Real-time monitoring systems track the machining process and provide feedback on deviations. This allows for adjustments on the fly, maintaining precision throughout the operation.

Have Questions?

Frequently Asked Questions

- What are the advantages of using a belt grinder?

- How does a bench grinder differ from other types of grinding machines?

- What are the most common applications for cylindrical grinders?

- What are the benefits of using a surface grinder for high-precision grinding and machining?

- What factors influence the precision and accuracy of a cylindrical grinder?

- What is the difference between jig grinding and jig boring?

- What parameters should be considered when selecting a grinding wheel?

Belt grinders have both speed and power, allowing the precision grinding machinist to finish projects much faster. Furthermore, because of the abrasiveness of the belt, the user doesn’t need to apply much pressure to shape the workpiece.

The bench grinder has two abrasive rotary grinding stones. One removes the material, while the other finishes it. This piece of equipment can be used to both sharpen tools and shape parts.

Cylindrical grinding is most often used for grinding tapered rods, shafts, axles, and spindles. In short, it’s ideal for workpieces that have a central axis of rotation.

Surface grinding makes it easy to attain smooth finishes on both metallic and non-metallic workpieces. It’s also highly efficient and accurate.

A quality cylindrical grinder typically has an accuracy of within 0.000025 mm. This range is affected by the material being ground, the area of contact, the wheel speed, and the machine’s horsepower.

Jig grinding yields complex geometrical shapes with extremely high precision. A similar specialty process, jig boring creates holes in the workpiece.

The material being ground is the single most important parameter to consider when selecting a CNC grinding wheel. Other factors to consider include the size of the workpiece, the surface speed, and whether coolant will be used.